Parts are coming together for a custom nautical style "explosion proof" lamp project. Consider something like this:

Matt's design is simpler, heavier and includes beautiful milk-colored hand blown glass. I spent this week in the machine shop making parts and here is a little progress.

Matt's design is simpler, heavier and includes beautiful milk-colored hand blown glass. I spent this week in the machine shop making parts and here is a little progress.silicon bronze welding on bulb socket holders:

detail for countersinking assembly screws:

Matt and I put our heads together, and he came up with a unique metal spinning set-up on a Logan engine lathe.

Matt and I put our heads together, and he came up with a unique metal spinning set-up on a Logan engine lathe.

The product:

The product:

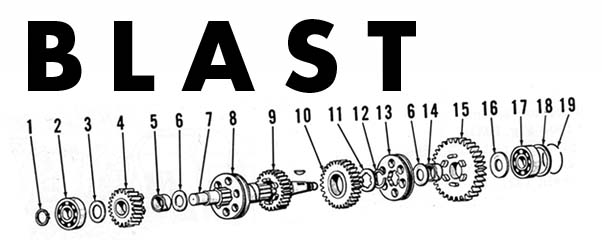

PARTS!

The lamps will be incorporated with original sea-fairing hardware.

More progress coming next week, at the shop of Bobs Welding.