This is a project I have been reading about and pondering for some time.. my first attempt was wildly hair-brained and hacked. I guessed on a bunch of figures than decided that air-forming would be easy and fun... That turned out to be a nice wind chime the first time around. Now, I have a thrice-read chapter of A.G. Bell's two stroke tuning under my belt, and I know more functions on a scientific calculator than I ever did before. Watching the guys at the

Moto-Matic moped shop and checking in on an old pal

Josh, from Ohio really inspired me to get moving on this, and i'm excited to try different designs in the future.

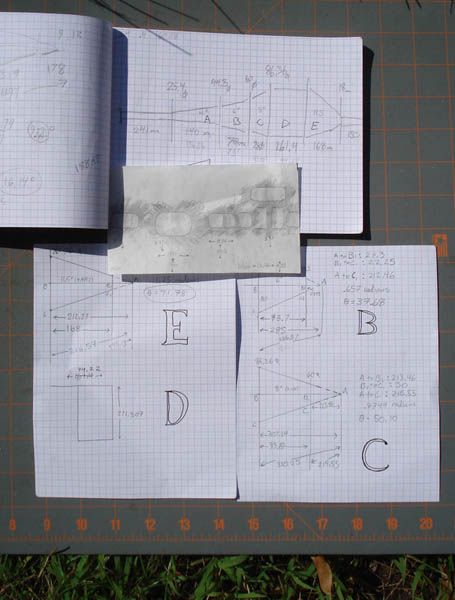

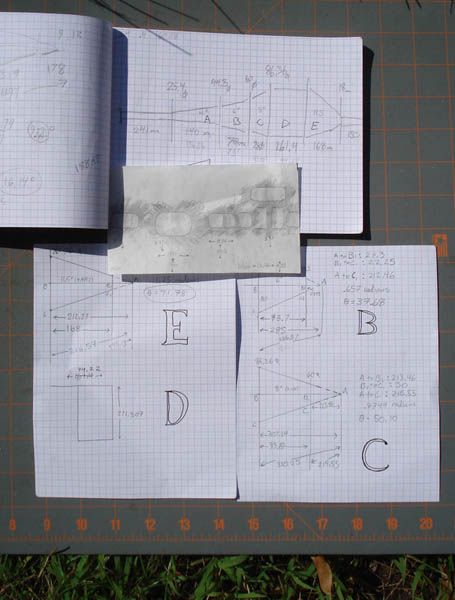

Homework for the past two weeks:

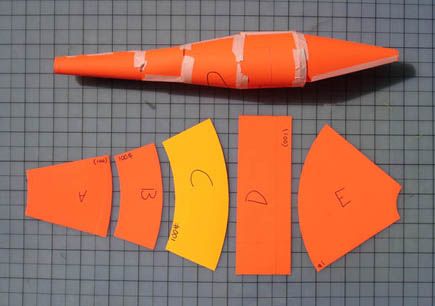

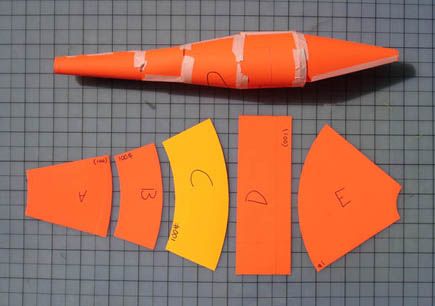

Mock-Up and Templates

So the next step is finding and cutting sheet metal, and ordering tubing for the header and stinger..